3D skin pack---The best package for steak

"Responsible packaging" is an emerging concept that refers to such a packaging, which can not only extend the long-term preservation time of food, but also have sustainability and promote a circular economy. It is with this concept in mind that chilled products have a new trend. Meat and seafood products are changing from modified atmosphere packaging to vacuum skin packaging.

Vacuum skin packaging is becoming more and more popular in Asia, and the increasingly affluent middle class is attracted by the differentiated, high-quality, high-end appearance. Vacuum skin-tight packaging closely adheres to the product like the skin. It protects the high quality of the food through tissue microbial growth, product dehydration, fat oxidation, vitamin and food flavor loss.

Juice is the key to the taste of steak. Steaks without juice, fried to the brim, cooked in place again, and tasted less mellow beef.

Steak juice is what we generally think of as "steak blood water", but it is not blood, but myoglobin. The reason it looks blood red is because myoglobin contains hemoglobin molecules.

In the process of regular slaughter, beef cattle will go through the process of bloodletting. In addition to a small amount of coagulation that may remain in the internal organs and blood vessels, there is almost no blood in the muscles. High-quality beef will also undergo acid removal and aging processes to further remove blood residues. This is why good beef does not need to be boiled when cooking. This process of blood water. The beef sold in the market basically does not carry "blood", so when we cut the steaks that are cooked 5 or even 3, the "blood water" that flows out is not blood, but myoglobin.

Vacuum packaging can't lock the juice. After the juice is drained, not only the flavor of the steak is lost, but also the tenderness of the steak is greatly reduced.

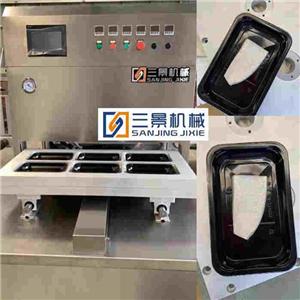

3D vacuum skin packaging, three-dimensional locking of the steak, every silk fiber of the steak is wrapped in plastic film, to avoid the loss of juice, and lock the most original taste of the steak.3D body-packing can extend the time for food safety from 10 days to 28 days, which is almost three times that of traditional modified atmosphere packaging. If the frozen steak is placed in the fresh-keeping layer, it can be stored for up to 1 month without deterioration.

For refrigerators that are precious every inch, saving space is undoubtedly the most important thing for packaging. The steaks in 3D skin pack are as thick as the steak itself. The plastic film is tightly attached to the steak to avoid wasting space and to store meat products reasonably. It is convenient and clear.