The Evolution of Multi-Functional Hot Forming Packaging Machines

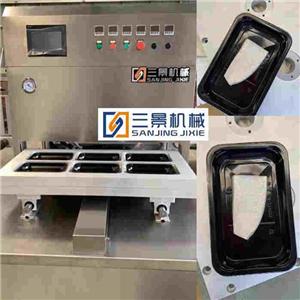

In today's dynamic packaging industry, advanced multi-functional hot forming packaging machines have emerged as game-changers. These innovative devices streamline the entire packaging process, seamlessly integrating container formation, filling, capping, and sealing into one seamless operation. Not content with standard capabilities, some cutting-edge models even incorporate vacuuming, gas inflation, and sterilization, ensuring enhanced product protection and extended shelf life.

There are three main categories based on their functionality, structure, and operational principles:

1. Intermittent Horizontal Hot Forming-Loading-Sealing Machines - These operate in a stop-and-go manner, adeptly handling tasks in batches, making them suitable for mid-sized operations with varying production needs.

2. Continuous Horizontal Hot Forming-Loading-Sealing Machines - Offering continuous production, these machines boast higher throughput and efficiency, ideal for high-volume production lines.

3. Hot Forming-Vacuum-Inflation Packaging Machines - Targeting industries that require a controlled atmosphere, these units create an optimal environment by evacuating air and introducing specific gases to maintain product freshness.

Each type caters to distinct market segments, providing tailored solutions for food, pharmaceutical, and other industries that prioritize quality, hygiene, and product integrity. By harnessing the power of automation and advanced technologies, these machines not only simplify processes but also contribute to the overall sustainability of packaging practices.

SEO Keywords: Multi-functional hot forming packaging, automated packaging systems, vacuum packaging, continuous production, sterilization, food packaging machinery, shelf-life enhancement.