Technological Innovations in Vacuum Skin Packaging for Beef

In the modern food industry, vacuum skin packaging, also known as modified atmosphere packaging (MAP), has revolutionized the preservation and presentation of beef products. To ensure optimal quality and freshness, several advanced technologies are employed when packaging beef in a vacuum-sealed format.

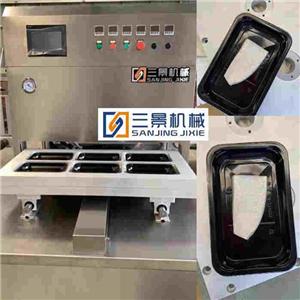

Firstly, high-quality vacuum machines are utilized. These devices extract air from the package, creating an anaerobic environment that inhibits bacterial growth and slows down enzymatic spoilage, prolonging the shelf life of the beef.

Secondly, barrier films with superior oxygen barrier properties are key. These films, typically made of polyethylene or polyester, prevent oxygen diffusion into the package while allowing moisture vapor to escape, maintaining ideal humidity levels for the meat.

Thirdly, advanced sensors and automation play a crucial role. These systems monitor temperature, humidity, and gas composition in real-time, ensuring the package remains at optimal conditions throughout the storage period.

Fourthly, Modified Atmosphere Packaging (MAP) techniques involve adjusting the gas composition within the package, often with a mixture of nitrogen and carbon dioxide. This further suppresses spoilage bacteria and maintains the red color of the beef.

Lastly, hygienic processing practices and strict quality control measures are implemented to minimize contamination during the entire packaging process.

In summary, the combination of vacuum technology, barrier materials, intelligent monitoring, and precise gas control is instrumental in preserving the freshness, flavor, and safety of vacuum skin-packed beef. This innovative approach ensures consumers receive high-quality, ready-to-use cuts of meat that maintain their appeal and nutritional value over extended periods.