Technology Advancements in Vacuum Skin Packaging for Seafood

Vacuum skin packaging for seafood employs cutting-edge techniques to preserve and enhance product quality. Key technologies include:

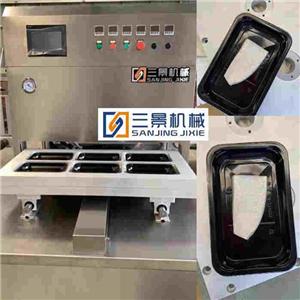

1. High-purity vacuum seals: Advanced sealing machines create an airtight seal to eliminate oxygen, delaying bacterial growth and maintaining freshness.

2. Opaque or transparent films: Barrier films adapt to seafood's specific needs, either blocking light to slow discoloration or allowing for visibility, maintaining consumer appeal.

3. Intelligent packaging systems: Sensors detect and adjust temperature and humidity to maintain ideal conditions for each seafood type, from delicate fish to shellfish.

4. Modified Atmosphere Packaging (MAP): Custom gaseous mixtures (e.g., CO2, N2, and oxygen levels) are controlled to inhibit spoilage and maintain texture.

5. Rapid cooling: Post-processing chillers ensure immediate vacuum packaging after catch, preserving natural flavors and preventing bacterial proliferation.

Overall, these technologies work together to deliver high-quality, visually appealing, and fresh-seeming seafood products, extending their shelf life and maintaining nutritional integrity.