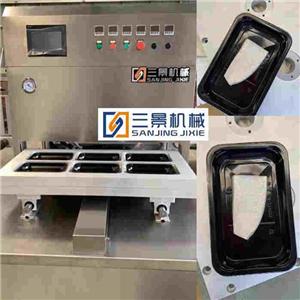

vacuum skin package

-

Vacuum Sealer Machine

The reason for wide and rapid development of vacuum skin pack is that the vacuum skin packaging machine can pack special-shaped products includes vegetables, meat and poultry, aquatic products, toys, small tools, electronic products, etc. The special shrink film affixed to the packaging is generally transparent, sticking tightly to the product, which can show the appearance of the product. Due to the uniform contraction, the special shrink film has a certain toughness, which is not easy to tear at edges and corners. Vacuum skin pack can put the scattered products together. Now, thanks to the successful development of vacuum skin packaging machine, vacuum skin pack can extend the storage period of food and convenient to store. Vacuum skin pack has the advantages of overall seal, moistureproof, antifouling, antirust effect, easy to pile up in the open environment and saving warehouse area; Vacuum skin pack process and equipment are simple, universal and easy to achieve mechanization which save human resources and packaging costs. Vacuum skin packaging machine ensures low packing cost, wide range of applications, reliable performance and high efficiency which is about 10 times more than manual packaging.

Email Details -

Shrimp Vacuum skin Packaging Machine

We welcome you to visit our factory with your product. You can test the package on our vacuum skin packaging machines and see the packaging effect, so that you can visually see the packaging appearance of the product, and it is easier to buy suitable equipment for your own products.

shrimp VSP machine shrimp vacuum skin packing machinery Red shrimp vacuum skin pack Black tiger shrimp vacuum skin package machineEmail Details -

Vacuum Skin Packaging Machinery

VSP-480TL fully automatic vacuum skin packaging machine/ vacuum skin packaging machinery: The fully automatic vacuum skin packaging machine independently research, development and produced by Shanghai Sanjing Machinery is suitable for large and medium-sized supermarkets and food processing plants. Applications include chilled fresh meat; frozen seafood, meat products and other fields. It has fast packaging speed, strong stability and high cost performance.

Email Details